Walkman PLD

Walkman PLD

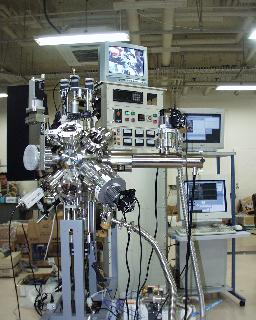

Fig. 1: The chamber soon after delivery with most of the larger vacuum components attached.

The PLD walkman project was set up to construct a compact Pulsed Laser Deposition chamber for use on a beamline 2 at the KEK Photon Factory synchrotron in Tsukuba. The main requirements for this chamber were:

These goals were achieved by using a spherical chamber design. The sample heating is done with a semiconductor laser. This has the advantage of moving all heater components out of the chamber and only the sample holder gets heated to the working temperature. The maximum temperature that can be achieved in this system is above 1200°C.

Probably the most common laser source for ablation in PLD systems is an excimer laser, such as a KrF laser working at 248 nm and typically delivering around 200 mJ in a 20 ns pulse. Excimer lasers are reliable, but require gas supplies, which must be properly vented to fulfill security requirements for halogen gases. Excimer lasers are also quite large and heavy, which makes their use on a beamline unpractical. This chamber gets around these problems by using a Nd:YAG pulse laser, which delivers up to about 100 mJ at 352 nm (3rd harmonic) in a 4 ns pulse. This laser is small enough to hold in your hand.

Fig. 1 shows the chamber during construction. The instrument rack holds all the electronics and also the sample heating laser. The computer rack has two displays, one for chamber control, and one for RHEED monitoring. The TV on top of the instrument rack is used to look at the sample during deposition. For safety reasons, users should not look directly into the chamber when the heating laser or the pulsed ablation laser is operating.