Oxide thin films

Transition metal oxide thin films are widely used for basic materials

science and in various device applications.

We study the properties of oxides in confined

geometries, typically in the form of thin films grown by

Pulsed Laser Deposition (PLD). PLD gives us the flexibility to work

with very many different oxide materials and to combine different

oxides in heterostructures. With the help of in-situ electron diffraction (RHEED),

oxide thin films can be grown with single atomic layer accuracy.

The pulsed deposition regime can be used to control the kinetics of crystal growth.

This is particularly useful in the growth of nanostructures.

Since films are grown on single crystal substrates, it is often possible to choose

the crystal orientation and the epitaxial strain state in a film.

You can read more here about the design and construction of the

PLD chambers that we use in our research.

Oxide photocatalysts

Solar-powered splitting of water into hydrogen and oxygen on

the surface of an oxide semiconductor photocatalyst carries the promise

of clean hydrogen fuel production. A new class of optical-quality

oxides is required for this technology to become competitive with

other solar energy capture techniques. Our purpose is to study

doping mechanisms of well-known wide-gap oxides to develop an oxide

semiconductor that is stable in water, has an optimal band gap for

absorbing sunlight and splitting water, and sufficiently low trapping and

recombination losses for high energy conversion efficiency.

Surfaces

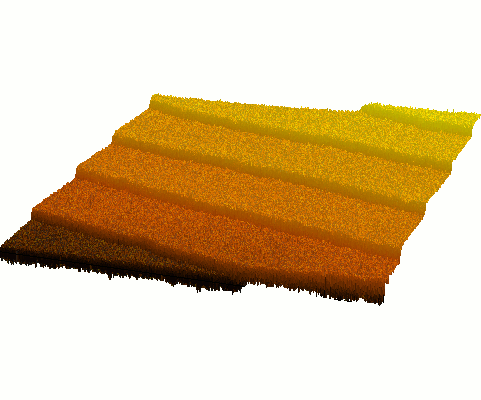

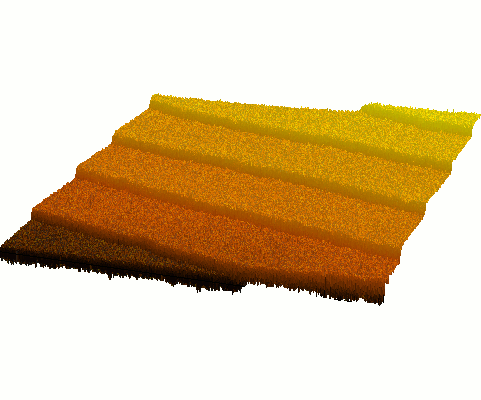

Thin films are usually grown on single-crystal substrates and the crystallinity

of the film is strongly affected by the morphology and stoichiometry of the

substrate surface. It is therefore desirable to start film growth

with an atomically flat surface that has a well-defined miscut angle

and direction. Preparation of such 'step-and-terrace' surfaces requires

a combination of polishing, annealing, and chemical etching treatments. The

surface morphology can be characterized by atomic force microscopy and in-situ

electron diffraction. The composition of the surface can be determined by

ion scattering spectroscopy. Read more on surface dynamics and SrTiO3

surface preparation:

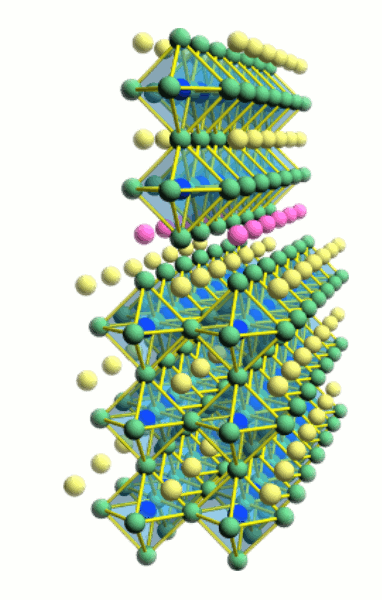

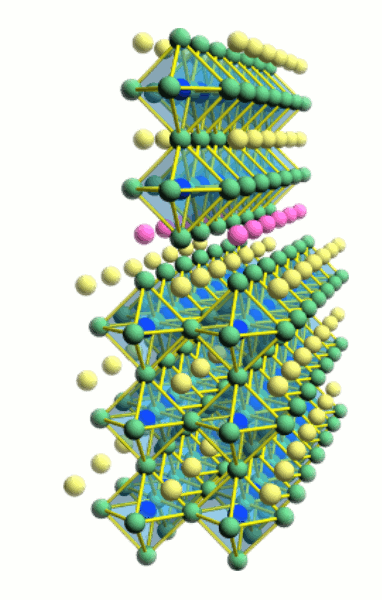

Interfaces

The properties of materials are different close to a surface

or an interface. In the simplest cases, the properties change due to

carrier density profiles caused by band bending, but more complex cases

are possible as well. The most interesting cases are those where completely

new phases appear at interfaces, such as metallic conductivity in an insulator

or magnetic order in a nonmagnetic host material.

Due to the layer-by-layer growth of thin films, it is possible to fabricate

atomically sharp interfaces and delta-doping layers. However, since oxide films

are grown at high temperature, it is always questionable whether the interfaces

are truly atomically sharp and no interdiffusion has occurred. Ion scattering

spectroscopy is a useful tool for analyzing interdiffusion in ultrathin oxide

films. Read more about film composition analysis and diffusion measurement:

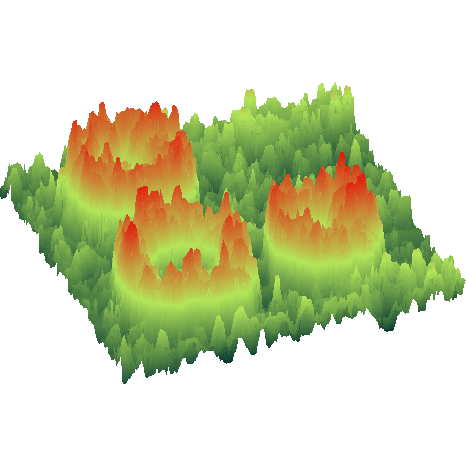

Nanostructures

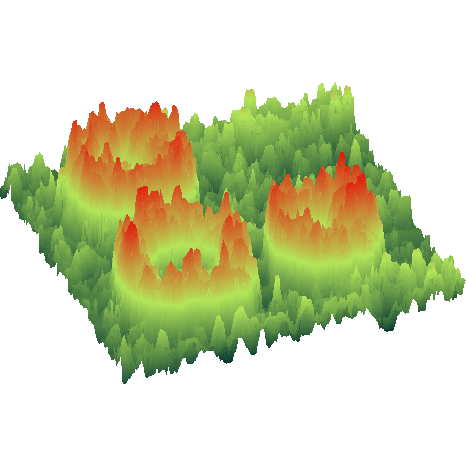

Combined thermodynamic and kinetic crystal growth control can be used to

grow a variety of oxide nanostructures. Fast growth at low temperatures nucleates

nanodots that can be grown into larger nanostructures, such as pyramids or pillars,

or annealed to form percolative nanostructure arrays. Slow growth at high temperature

can be used to fabricate nanowires on step-and-terrace crystal surfaces. As long as

the nanostructure growth remains epitaxial, cation interdiffusion is minimal and

even single unit cell nanostructures are stable. Read more about the materials and types

of oxide nanostructures that can be grown by pulsed laser deposition: