Laser heated mini-PLD

Laser heated mini-PLD

The Mini PLD chamber was the first prototype system that used laser heating for sample temperature control in a pulsed laser deposition system. The heating laser is a 300W cw industrial YAG laser that is designed for cutting and welding. In this case it is used to control the temperature of a small (up to 10mm x 10mm) sample. The system can heat and cool samples very rapidly, even in a pure oxygen atmosphere. There is practically no temperature limit since the power of the laser is sufficient to melt oxides such as sapphire or SrTiO3.

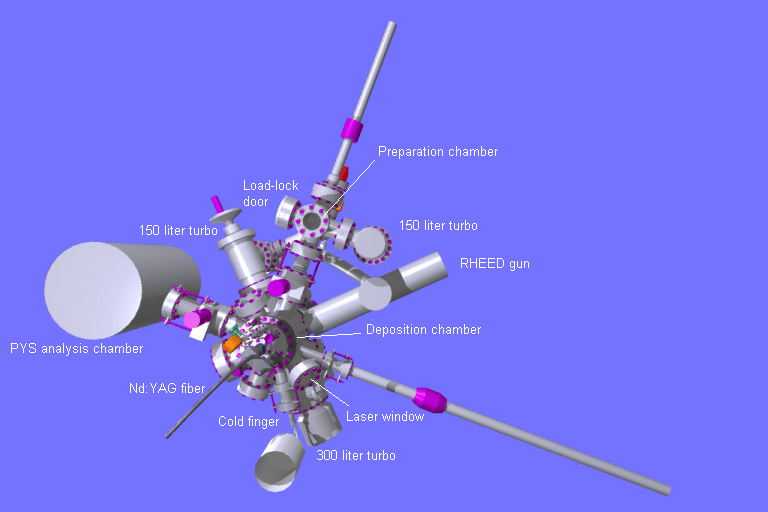

The chamber views below give a geneal idea of the chamber layout and the basic accessories attached to the system. In the images below, the chamber is shown in a configuration where a photoelectron total yield spectrometer is attached to one of the sample transfer ports.

Top view of the chamber