Walkman PLD

Walkman PLD

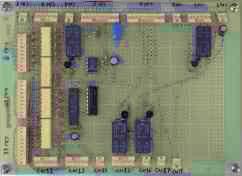

Fig. 1: Analog signal connections

Fig. 2: Digital signals controller

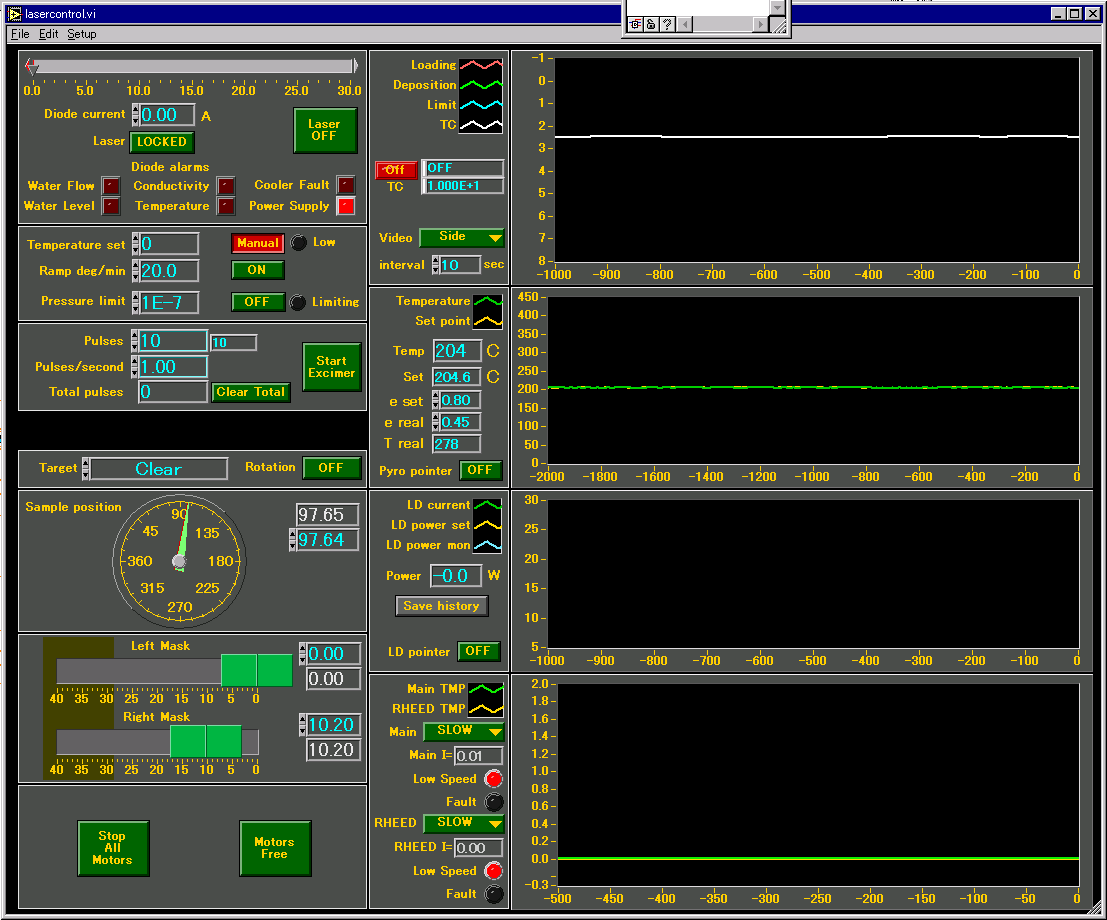

Nearly all functions of the chamber are under computer control. The control system is based on LabVIEW and NI's multifunction and motor control boards. Most of the analog signals are routed through a front-panel connection box (Fig. 1), allowing for easy checking of signals for diagnostic purposes. Most of the digital signals pass through a control board which holds optical isolators and couple of relays for signal routing (Fig. 2).

The chamber has 5 stepper motors for controlling sample rotation, left and right mask movement, target carousel rotation, and the target carousel flip motion. A speed-controlled AC motor is used for continuous target rotation during ablation. All motors are driven by the computer for automated depositions.

The sample temperature is monitored by the computer using an optical pyrometer to perform PID temperature control of the heating laser power. The system also monitors the laser cooling and will cut the laser in case of chiller malfunction. The heating laser is directly interlocked to the cooling water flow switch and power supply alarms.

The vacuum levels in the chamber and at the rotary pumps are monitored. Automatic pressure control is possible with a pulse valve or a piezo valve.

Fig. 3: LabVIEW control panel of chamber functions.

The target materials and positions can be preprogrammed and easily selected from the computer. Since the computer has control over all process parameters, fully standalone, scripted operation is possible.

Various other system characteristics are monitored and recorded for maintenance and documentation purposes. This includes all motor positions, heating laser drive current and the photodiode signals, turbo pump powers levels, etc.

The YAG laser is a flashlamp based system that operates at a single fixed pulse rate. Variable pulse rates are possible by computer control of the laser Q-switch. The Q-switch timing relative to the flashlamp firing is used for tuning the ablation laser pulse energy.

The chamber control program can interact with the RHEED monitoring system for electron diffraction feedback to the deposition system