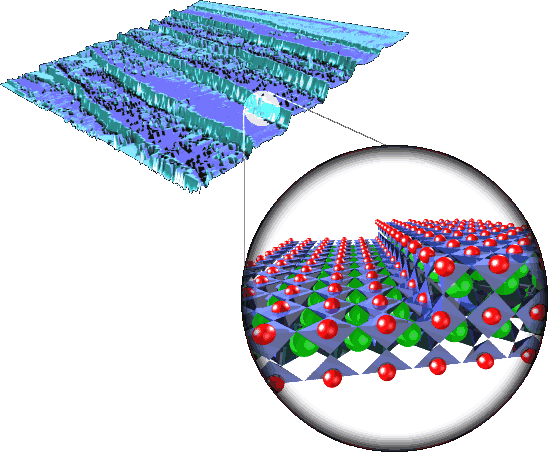

Ideally, thin film growth should start with a

step-and-terrace surface where all step edges

have equal, single unit cell height (0.4 nm for SrTiO3) and the steps

should be approximately parallel and equidistant. For heterostructure

and ultrathin layer studies, it is also important to ensure that the

terminating layer of the surface is well controlled. In the case of SrTiO3 (001) substrates,

the crystal can be terminated either by a SrO or a TiO2 layer.

Since the TiO2 layer is more stable, we usually try to prepare

a uniform TiO2 termination.

Although AFM images cannot identify whether the surface terminates with the

SrO or the TiO2 layer, a uniform terminating layer can be assumed

if all step edges have equal 0.4 nm height. To obtain such surfaces,

a substrate usually goes through several processing steps.

SrTiO3 substrate preparation steps

This is what a polished substrate looks like when imaged by AFM.

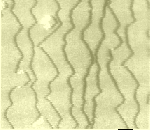

It is possible to obtain a step surface by annealing a polished

substrate at low oxygen pressure, but this leaves the surface

with a mixed termination, with some parts covered by a SrO layer

and other places by a TiO2 layer.

Wet etching is chemically selective. The buffered HF removes

preferentially Sr, ensuring that the surface is purely Ti terminated. Despite near-perfect

stoichiometry, an etched surface is not stable at high temperature.

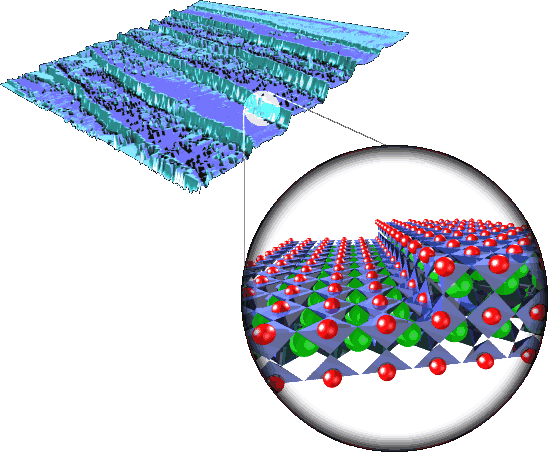

Annealing at low oxygen pressure gives a near-perfect

step-and-terrace surface, which is mostly Ti terminated. There are no macroscopic

Sr islands on this surface. All steps have single unit cell, 0.4 nm height.

Steps are not bunched and the step direction is determined by the crystal

miscut direction.

The annealed surface often shows a 2×2 reconstructed

RHEED pattern. A rather well ordered structure on the unit cell scale can be obtained

by long annealing at relatively low temperature.